I have seen some contractors bash the use of sealers on their websites. They try to sell you the idea that the contractors using sealers are just trying to skimp on costs by skipping the first coat of polyurethane. These contractors are misinformed. Manufacturers and the National Wood Flooring Association both strongly recommend using sealers, especially when using water-based polyurethanes.

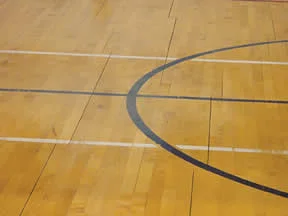

For those who don't know, a sealer is a coat applied before the final polyurethane step. A sealer can be applied to raw wood for a natural look or over the stain of your choice. It is recommended to use one to two coats of sealer followed by two coats of polyurethane instead of the alternative three-coat of the poly method. Water-based polyurethane is strong enough that, when it is applied and seeps into the cracks, it acts as a glue and bonds the boards together; this is called side bonding, and when done in large chunks, it is called panelization (see photo below). You run into a problem when the wood shrinks in the low humidity months and pulls apart from itself in large chunks. Using a sealer is one way to help prevent this problem. Another way to avoid that type of shrinkage is to run a whole home humidifier and keep your house between 35% and 55% relative humidity.

Tannin bleed is an issue that occurs when water-based polyurethanes pull up the tannins in the wood and leave stains. Sealers help prevent this problem, which can frequently happen in wood species with many naturally occurring tannins like white oak.

If you fail to follow the manufacturer's process, you risk suffering severe damage to your new floors, including shifting and splitting boards and ugly stains. My advice is to do your research. Manufacturers stress the importance of sealers for a reason, and the benefits of following this protocol far outweigh the risks you run by neglecting this step in the process.

Panelization